Ever stared at a wheel, mesmerized by the intricate dance of its lug nuts, wondering what secrets lie within that circular arrangement? That, my friend, is the realm of the wheel bolt pattern, a critical piece of the automotive puzzle that dictates whether a wheel will fit your vehicle or send you spinning into a world of frustration. Understanding and accurately measuring this pattern is paramount, a ritual every car enthusiast, mechanic, or even the casually curious should master. This is your guide to decoding the secrets of the wheel bolt circle.

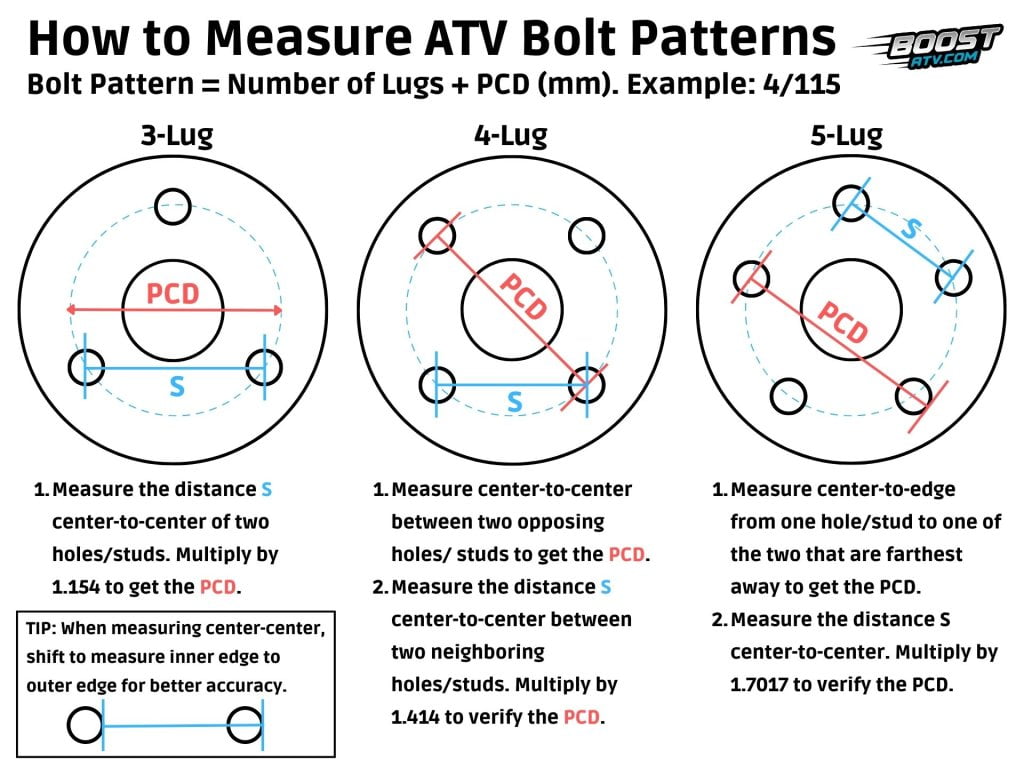

The bolt pattern, also known as the bolt circle or PCD (pitch circle diameter), is the diameter of an imaginary circle that passes through the center of each wheel stud or bolt hole. This seemingly simple measurement is the keystone of wheel fitment. An incorrect bolt pattern means the wheel won't mount flush, leading to vibrations, potential damage, and a generally unsafe driving experience. Imagine the chaos of a wheel detaching mid-drive - a nightmare scenario easily avoided with the right knowledge and tools.

Wheel bolt pattern gauges, digital calipers, and even rulers can be employed in this crucial measurement process. Each tool offers varying degrees of precision and ease of use. The simplest method often involves a ruler or tape measure for direct measurement between opposite studs, but for more complex patterns, a dedicated wheel bolt pattern gauge provides the most accurate readings. These tools are relatively inexpensive and can save you from costly mistakes and potential hazards down the road.

The history of the wheel bolt pattern is intrinsically linked to the evolution of the automobile itself. As cars evolved, so did the need for standardized wheel fitment. Early vehicles often had bespoke wheel designs, making replacements difficult and expensive. The standardization of bolt patterns simplified manufacturing, improved safety, and opened up a world of aftermarket wheel options. This seemingly small development revolutionized the automotive industry and continues to play a vital role today.

One of the main issues surrounding bolt pattern measurement is the potential for human error. Misreading a measurement, even by a fraction of an inch, can lead to purchasing the wrong wheels. This is where accurate measurement tools and a clear understanding of the measurement process become paramount. Double-checking your measurements and consulting fitment guides can save you from the headache and expense of returning ill-fitting wheels.

The benefits of accurately measuring wheel bolt patterns are threefold: safety, performance, and aesthetics. A correctly fitted wheel ensures a secure and stable connection, minimizing the risk of wheel detachment. It also optimizes performance by ensuring proper weight distribution and handling. Finally, the right wheels enhance the overall appearance of your vehicle, allowing you to personalize your ride.

To accurately measure your bolt pattern, first identify the number of lugs or bolts. Then, using a wheel bolt pattern gauge or caliper, measure the distance between the center points of opposite studs (for an even number of lugs) or use a dedicated tool or calculation for odd-numbered lug patterns. Finally, compare your measurement to fitment guides to confirm the correct bolt pattern for your vehicle.

Advantages and Disadvantages of Different Bolt Pattern Measurement Tools

| Tool | Advantages | Disadvantages |

|---|---|---|

| Ruler/Tape Measure | Simple, readily available | Less accurate, difficult for complex patterns |

| Caliper | More precise than a ruler | Can be challenging for odd-numbered lug patterns |

| Wheel Bolt Pattern Gauge | Easiest and most accurate, specifically designed for the task | Requires a specific tool |

Five best practices include using the right tool for the job, double-checking measurements, consulting fitment guides, cleaning the wheel hub for accurate readings, and seeking professional help when in doubt.

Frequently Asked Questions (FAQs): What is a wheel bolt pattern? How do I measure it? What happens if I use the wrong bolt pattern? Where can I find bolt pattern information for my car? What tools are available for measuring? How accurate do my measurements need to be? Can I measure the bolt pattern myself? What if I have an odd number of lugs?

One handy tip is to take a picture of your current wheel's bolt pattern for reference. Another trick is to use a piece of cardboard to create a template of the bolt holes.

In conclusion, understanding and accurately measuring wheel bolt patterns is essential for safe and optimal vehicle performance. From ensuring a secure wheel fitment to enhancing your vehicle's aesthetics, the correct bolt pattern is a critical detail that shouldn't be overlooked. By utilizing the right tools and techniques, and following best practices, you can confidently navigate the world of wheel fitment and ensure a smooth and safe ride. Don't underestimate the power of this small but mighty measurement; take the time to learn it, master it, and empower yourself with the knowledge to make informed decisions about your vehicle. This investment in knowledge will pay dividends in safety, performance, and peace of mind, allowing you to enjoy the open road with confidence. So, the next time you gaze at a wheel, remember the secrets hidden within those bolt holes and the importance of accurate measurement. Take the time to decipher the code, and you'll unlock a world of possibilities for your vehicle.

Unpacking 21 savages arrival when did the savage era begin

Unlocking anime exploring free and accessible streaming

Wellbeing in new milford exploring the towns health department