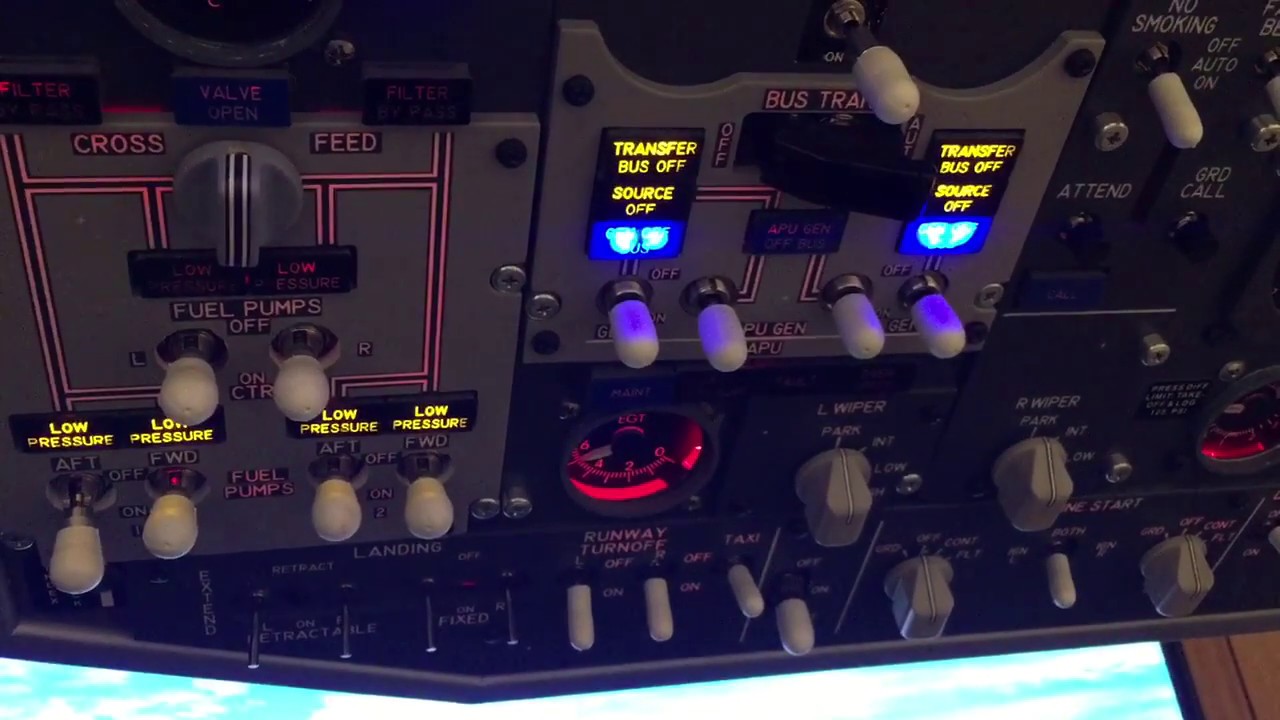

Ever wondered what propels the iconic Boeing 737 through the skies? It's a question that sparks curiosity, especially considering the sheer size and weight of this ubiquitous airliner. The answer, while seemingly simple, unravels a fascinating story of engineering evolution, efficiency pursuits, and even controversy.

The 737, throughout its various iterations, hasn't relied on a single engine type. Its power plants have evolved significantly since the aircraft's debut in the late 1960s. Early models utilized low-bypass turbofan engines like the Pratt & Whitney JT8D, recognizable for their distinctive, smoky exhaust. These engines served as the workhorses of the early 737 generations, providing the necessary thrust for shorter routes.

As the 737 family grew, so did the demand for more fuel-efficient and quieter engines. The introduction of high-bypass turbofan engines like the CFM56 series marked a significant leap forward. These engines, developed by CFM International (a joint venture between GE Aviation and Safran Aircraft Engines), revolutionized the 737's performance, contributing to its global popularity. The CFM56’s larger fan diameter and improved design drastically reduced noise and fuel consumption, making the 737 a more economical and environmentally friendly aircraft.

The 737 MAX, the latest generation, features the LEAP-1B engine, also manufactured by CFM International. These engines boast even greater fuel efficiency and reduced emissions compared to their predecessors. However, the LEAP-1B engine has also been the subject of intense scrutiny following two tragic accidents. The subsequent investigations brought to light issues with the engine's placement and its interaction with the aircraft's flight control systems.

Understanding the 737's engine evolution provides insights into the ongoing advancements in aviation technology. Each generation reflects a drive for improved performance, reduced environmental impact, and enhanced passenger comfort. From the smoky plumes of the early JT8D to the quieter, more efficient LEAP-1B, the journey of the 737's engines mirrors the constant pursuit of innovation within the aerospace industry.

The history of the 737 engine is a testament to the constant drive for improvement in aviation. From noise reduction to fuel efficiency and power output, each new engine iteration has sought to address limitations and push the boundaries of technology. The importance of the engine choice lies in its direct impact on the aircraft's performance, operational costs, and environmental footprint.

Advantages and Disadvantages of the LEAP-1B

| Advantages | Disadvantages |

|---|---|

| Improved Fuel Efficiency | Initial Safety Concerns (MCAS) |

| Reduced Noise Levels | Ground Clearance Issues (Necessitating design changes) |

| Lower Emissions |

Frequently Asked Questions:

1. What engines are used on the 737 MAX? Answer: LEAP-1B

2. What engines were used on the original 737? Answer: Pratt & Whitney JT8D

3. Why did the 737 switch to CFM56 engines? Answer: For better fuel efficiency and noise reduction.

4. What is a high-bypass turbofan engine? Answer: An engine that directs a significant portion of air around the core for increased efficiency.

5. What is the significance of the LEAP engine? Answer: Increased efficiency and reduced emissions, but also faced initial safety challenges.

6. What caused the issues with the 737 MAX engines? Answer: The engine's placement and interaction with the MCAS system.

7. Are the 737 MAX engines safe now? Answer: Following modifications and rigorous testing, the aircraft has been recertified.

8. What is the future of 737 engines? Answer: Continued focus on sustainability and further improvements in efficiency are expected.

Tips and Tricks Related to the 737 Engine: For those interested in further learning, research the specifics of engine maintenance procedures and the technological advancements incorporated into each engine generation. Exploring the history of CFM International and its collaboration with Boeing also provides valuable context.

In conclusion, understanding the engines that power the Boeing 737 is crucial to appreciating the aircraft's evolution and its impact on the aviation industry. From the early JT8D to the modern LEAP-1B, the progression of engine technology has driven improvements in fuel efficiency, noise reduction, and overall performance. While the 737 MAX and its LEAP engines faced significant challenges, the subsequent investigations and modifications underscore the critical importance of safety and continuous improvement in aerospace engineering. The future of the 737, and indeed the entire aviation sector, hinges on the continued development of sustainable and efficient engine technologies. Further research into the specifics of each engine type, their performance characteristics, and the ongoing efforts to enhance their capabilities is encouraged for a deeper understanding of this crucial aspect of air travel.

Stalking your perfect pre owned rav4 hybrid the ultimate guide

Grandson tattoos for grandpa a lasting bond in ink

A magical beginning planning the ultimate disney world baby shower