Ever stared at a tangled mess of wires under your car's dashboard and felt a wave of dread wash over you? Fear not, fellow motorists! Electrical gremlins can be intimidating, but they don't have to drain your wallet. This article dives deep into the world of automotive wire harness repair, empowering you to tackle those electrical issues head-on and keep your hard-earned cash in your pocket.

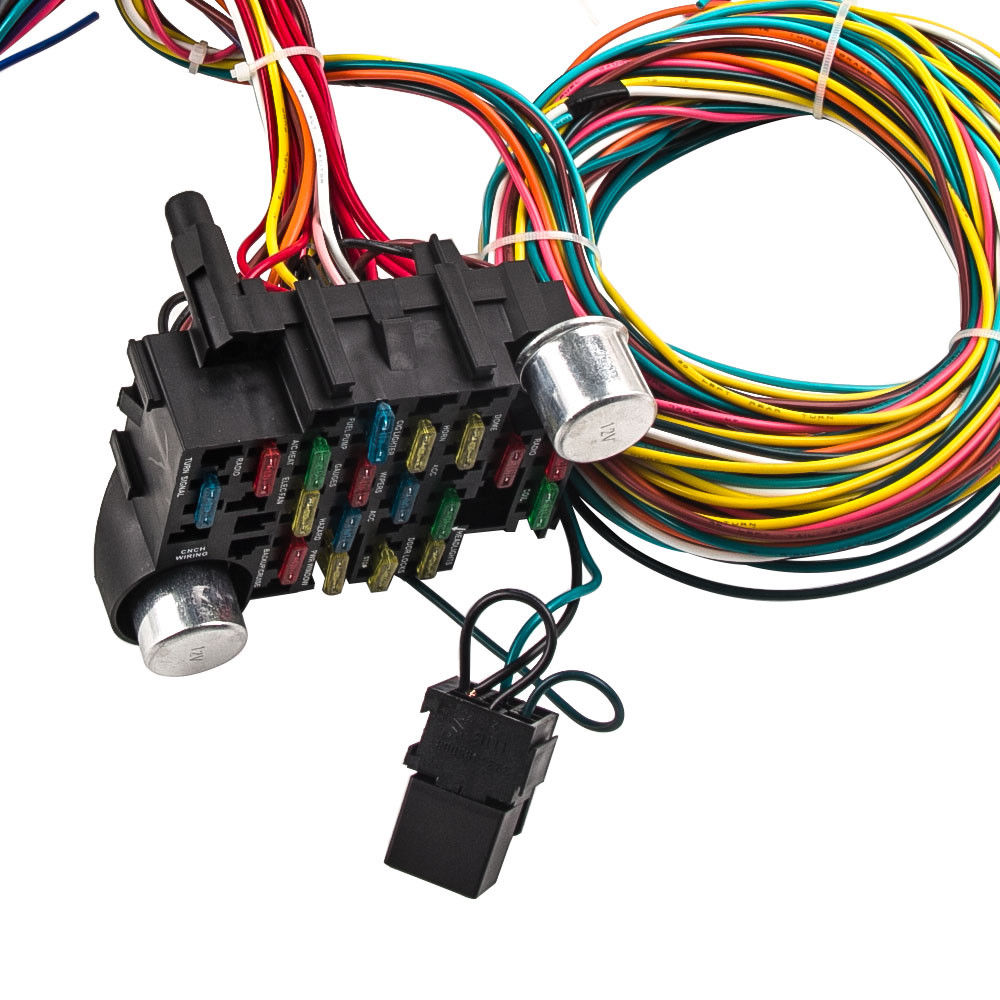

Automotive wire harnesses are the nervous system of your vehicle, transmitting vital signals that control everything from your headlights to your engine. Over time, these harnesses can become damaged due to wear and tear, exposure to the elements, or even rodent infestations. Replacing an entire harness can be incredibly expensive, but often, a simple repair is all that's needed. That's where automotive wire harness repair kits come in. These kits provide the tools and materials you need to fix damaged wires, connectors, and terminals, saving you a significant amount of money compared to a full replacement.

The history of automotive wire harnesses is intertwined with the evolution of the automobile itself. Early cars had simple electrical systems with minimal wiring. As cars became more complex, so did their electrical systems, leading to the development of the bundled wire harness. Repairing these harnesses initially involved a lot of improvisation, with mechanics often having to fabricate their own repair solutions. Thankfully, pre-packaged automotive wire harness repair kits have simplified the process, making it accessible to DIYers and professionals alike.

The importance of a properly functioning wire harness cannot be overstated. A faulty harness can lead to a wide range of problems, from flickering lights and malfunctioning accessories to complete electrical system failure. Ignoring these issues can not only be inconvenient but also dangerous, potentially leading to breakdowns or even accidents. Understanding how to use an automotive wire harness repair kit is crucial for maintaining the safety and reliability of your vehicle.

Common issues that necessitate the use of a car wire harness repair kit include broken wires, corroded terminals, damaged connectors, and rodent damage. Identifying the specific problem is the first step in choosing the right repair solution. These kits usually contain items such as heat shrink tubing, electrical tape, wire connectors, terminals, and sometimes even specialized tools for crimping and stripping wires.

Benefits of using these kits include cost savings (compared to full harness replacements), convenience, and the satisfaction of fixing something yourself. For example, a broken wire in a headlight harness can be easily repaired with a few dollars’ worth of supplies from a kit, while a full harness replacement could cost hundreds.

An action plan for harness repair involves: 1) Identifying the problem; 2) Disconnecting the battery; 3) Locating the damaged section of the harness; 4) Repairing the damaged area using the appropriate tools and materials from the kit; 5) Testing the repair; and 6) Reconnecting the battery.

Advantages and Disadvantages of Automotive Wire Harness Repair Kits

| Advantages | Disadvantages |

|---|---|

| Cost-effective | Requires some basic electrical knowledge |

| Convenient | May not be suitable for all types of damage |

| Empowering (DIY) | Requires proper tools for best results |

Five best practices: 1) Always disconnect the battery before working on any electrical components. 2) Use the correct gauge wire for the repair. 3) Use high-quality heat shrink tubing to protect the repair. 4) Properly crimp terminals and connectors. 5) Thoroughly test the repair before reconnecting the battery.

Five real examples: 1) Repairing a broken turn signal wire. 2) Fixing a corroded connector in a tail light assembly. 3) Splicing in a new wire for an aftermarket accessory. 4) Repairing rodent damage to a wiring harness. 5) Replacing a damaged connector in an engine sensor harness.

Five challenges and solutions: 1) Difficulty accessing the damaged area – Solution: Use specialized tools or remove components to gain access. 2) Identifying the correct wire – Solution: Consult wiring diagrams. 3) Improper crimping – Solution: Use a proper crimping tool and practice. 4) Heat shrink tubing not shrinking properly – Solution: Use a heat gun with the correct temperature setting. 5) Repair not lasting – Solution: Ensure proper connection and use high-quality materials.

FAQ: 1) What tools do I need? 2) Where can I buy repair kits? 3) What gauge wire should I use? 4) What type of connectors should I use? 5) How do I crimp terminals? 6) How do I use heat shrink tubing? 7) How do I test my repair? 8) Where can I find wiring diagrams?

Tips and tricks: Use a multimeter to test for continuity. Label wires before disconnecting them. Take pictures before and during the repair process. Use dielectric grease on connectors to prevent corrosion. Invest in a good set of crimping tools.

In conclusion, automotive wire harness repair kits are invaluable tools for any car owner looking to save money and maintain their vehicle's electrical system. They empower you to tackle common electrical problems without the expense of professional repairs or full harness replacements. By understanding the basics of wire harness repair and following best practices, you can keep your car running smoothly and reliably for years to come. Mastering this skill not only saves you money but also grants you the satisfaction of taking control of your car's maintenance. So, next time you encounter an electrical gremlin, don't panic – grab your repair kit, roll up your sleeves, and get ready to fix it yourself. Your wallet and your car will thank you.

Mastering single digit addition a comprehensive guide

Exploring the beauty of short spanish rhyming poems

Navigating the global flow international wire transfers with wells fargo