Securing flanges reliably is crucial in numerous industrial applications, from pipeline systems to pressure vessels. Understanding the specifications of the bolts used in these connections is paramount for maintaining safety and preventing leaks. This is where flange bolt charts become indispensable tools for engineers and technicians. These charts, often available as downloadable PDFs, provide a consolidated reference for various bolt dimensions, materials, and tightening torques.

Imagine trying to assemble a complex flange connection without readily available bolt specifications. The process could be riddled with errors, leading to potential failures and costly downtime. A flange bolt dimension chart simplifies this process significantly, offering quick access to crucial information such as bolt diameter, length, thread pitch, and head dimensions. This readily available data ensures the right bolts are used for each specific flange, minimizing the risk of improper assembly.

The history of flange bolt standardization goes hand-in-hand with the development of industrial processes. As industries evolved and the need for standardized components grew, so did the need for reliable bolt specifications. Flange bolt charts, initially presented in printed manuals, have evolved into easily accessible digital formats like PDFs. This transition has made accessing critical bolt information much more convenient for professionals in the field.

The core purpose of a flange bolt specification chart PDF is to provide a comprehensive and readily available reference for all relevant bolt dimensions and properties. These documents often include information on materials, grades, and tightening torques. This centralized information is essential for maintaining consistency in flange assembly and ensuring the integrity of the connection. Imagine the consequences of using an incorrect bolt grade – it could lead to premature failure and potentially dangerous situations.

A common issue encountered when dealing with flange bolts is identifying the correct bolt size and grade for a particular flange. Flange bolt charts directly address this issue by providing a clear and concise overview of the necessary specifications. For example, a flange bolt size chart PDF might include a table listing different flange sizes and their corresponding bolt diameters, lengths, and grades. This eliminates guesswork and ensures the proper bolt is selected for the job.

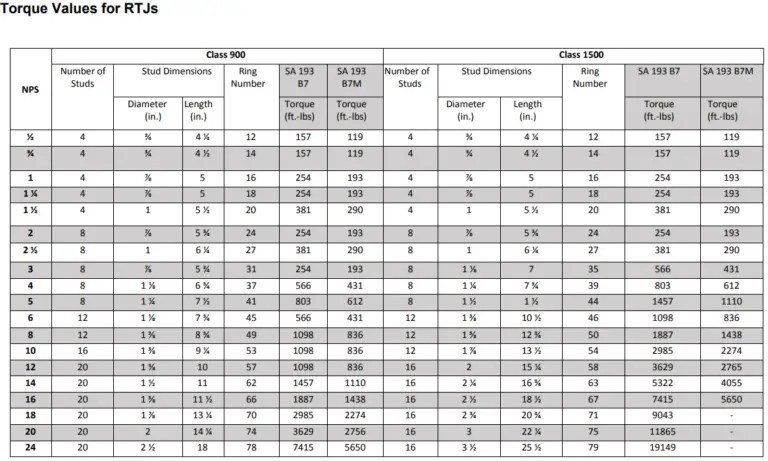

A flange bolt torque chart specifies the correct torque values for different bolt sizes and materials. Applying the correct torque is crucial to prevent over-tightening or under-tightening, both of which can compromise the flange connection. A torque chart often accompanies a standard bolt chart, providing a complete guide for proper assembly.

One benefit of using a flange bolt chart is improved accuracy in bolt selection. Another benefit is enhanced safety, as using the correct bolt specifications reduces the risk of leaks and failures. Furthermore, these charts improve efficiency by streamlining the assembly process and reducing the time spent searching for information.

When utilizing a flange bolt chart, follow these steps: identify the flange size and pressure rating, consult the chart to determine the appropriate bolt dimensions and grade, and apply the recommended torque values during assembly. An example of successful implementation would be a refinery using a flange bolt chart PDF to ensure consistent and reliable flange connections throughout their piping systems.

Advantages and Disadvantages of Using Flange Bolt Chart PDFs

| Advantages | Disadvantages |

|---|---|

| Easy access to information | Potential for outdated versions |

| Standardization of bolt selection | Requires access to a PDF reader |

| Improved safety and reliability | Can be overwhelming for beginners |

One best practice is to always verify the chart's source and ensure it’s up-to-date. Another is to use calibrated torque wrenches for tightening bolts. It’s also essential to properly lubricate the bolts and gaskets. Regularly inspecting flange connections is crucial, as is documenting all assembly procedures.

FAQs:

Q: Where can I find a flange bolt chart PDF? A: Industry organizations and fastener manufacturers often provide these charts on their websites.

Q: What information is typically included in a flange bolt chart? A: Bolt dimensions, materials, grades, and torque specifications.

Q: Are all flange bolt charts the same? A: No, they can vary depending on the flange standard being used (e.g., ANSI, DIN, JIS).

Q: How often should I refer to a flange bolt chart? A: Whenever assembling or maintaining flange connections.

Q: What is the importance of using the correct torque? A: Proper torque ensures a secure seal and prevents damage to the flange or bolts.

Q: How are flange bolt charts used in different industries? A: They are used across various industries like oil and gas, chemical processing, and power generation to ensure reliable flange connections.

Q: What are some common challenges in using flange bolt charts? A: Ensuring the chart is up-to-date and interpreting the information correctly.

Q: What are the consequences of using the wrong bolt? A: Leaks, failures, and potential safety hazards.

A tip for using flange bolt charts is to print a physical copy and keep it readily available in the workspace. This can be particularly helpful in environments where electronic devices are not permitted. Always double-check the chart’s information before proceeding with assembly.

In conclusion, flange bolt charts, particularly those available in PDF format, play a vital role in ensuring the safe and reliable assembly of flange connections. They provide a centralized source of crucial information, including bolt dimensions, materials, and torque specifications. By using these charts correctly and following best practices, engineers and technicians can significantly reduce the risk of leaks, failures, and potential safety hazards. Access to reliable information, like that found in a flange bolt chart PDF, is a cornerstone of safe and efficient industrial operations. Understanding and correctly applying the information within these charts is essential for anyone working with flanged connections. Take the time to familiarize yourself with these resources and make them an integral part of your maintenance and assembly procedures. Invest in proper training and stay updated with the latest industry standards to ensure optimal performance and safety.

Mastering the art of smiley faces on your pc keyboard

Ea fc 24 launch troubles on windows 10

Easy and beautiful drawings for printing