Ever stared at your wheels and wondered about that mysterious arrangement of bolts? It's more than just a design feature – it's your lug nut pattern, a crucial piece of information for anyone who owns a car. Getting it wrong can lead to wobbly wheels, stripped bolts, and even dangerous driving conditions. So, let's dive deep into the world of lug nut patterns and unravel its secrets.

Measuring a lug nut pattern, often referred to as bolt pattern or PCD (Pitch Circle Diameter), is essential for proper wheel fitment. It's the key to ensuring your wheels are securely attached to your vehicle. This pattern is defined by the number of lugs and the diameter of the circle on which they are positioned. Without accurately determining this pattern, you risk damaging your wheels, studs, and potentially jeopardizing your safety on the road. So, how do you decipher this code of your wheels?

The history of the lug nut pattern is intertwined with the evolution of the automobile itself. As cars developed, so did the need for standardized and secure methods of attaching wheels. Early designs were often bespoke, leading to compatibility issues. Over time, standard patterns emerged, making it easier to manufacture and replace wheels. The importance of this standardization cannot be overstated. It ensures interchangeability, allowing drivers to replace damaged wheels with compatible options from various manufacturers.

The main issue surrounding lug nut pattern measurement is the potential for errors. Incorrect measurements can lead to purchasing the wrong wheels. Imagine the frustration of receiving new wheels only to discover they don't fit your car! Accurate measurement is vital. Several tools, from simple rulers to dedicated lug nut pattern gauges, are available to help determine the correct pattern.

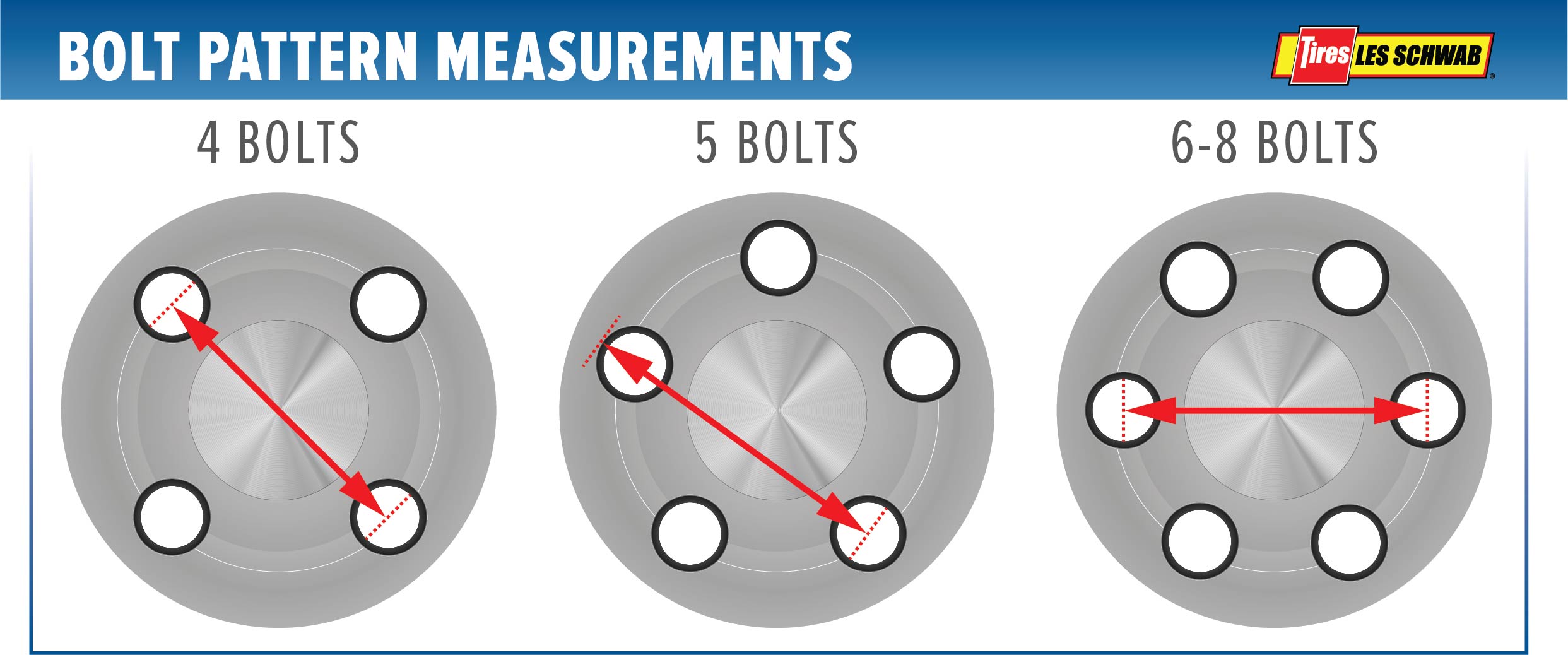

Let's break down the process. For a four or six-lug pattern, measure the center-to-center distance between two opposite lug nuts. For five-lug patterns, things get a little trickier. You'll need to measure from the back of one lug nut to the center of the opposite lug nut. This measurement will be close but may require further refinement using a lug nut pattern gauge or an online calculator, factoring in the stud size. This may seem complex, but with the right tools and a bit of practice, you can become proficient in determining your lug nut pattern.

Three benefits of correctly measuring your lug nut pattern include: Safety: Correct fitment prevents wheel detachment, ensuring your safety on the road. Avoiding Damage: Proper measurements prevent damage to your wheel studs and hubs. Cost Savings: Accurate measurement prevents purchasing incorrect wheels, saving you time and money.

Here's a step-by-step guide: 1. Identify the number of lug nuts. 2. Measure accordingly, using a ruler or caliper. 3. Double-check your measurements. 4. Use an online calculator for five-lug patterns if necessary.

Advantages and Disadvantages of Measuring Lug Nut Pattern

| Advantages | Disadvantages |

|---|---|

| Ensures proper wheel fitment | Can be tricky for 5-lug patterns |

| Enhances safety | Requires accurate measurement tools |

| Prevents damage to vehicle |

Five Best Practices: 1. Use the right tools. 2. Double-check measurements. 3. Consult online resources. 4. Clean the wheel hub for accurate measurement. 5. If unsure, consult a professional.

Five Real Examples: A common pattern is 5x114.3, found on many Honda and Toyota vehicles. Another is 5x100, common on Subaru models. 4x100 is found on smaller cars. 6x139.7 is often found on trucks. 5x120 is seen on BMWs.

Five Challenges and Solutions: 1. Rusty lugs: Use penetrating oil. 2. Difficulty measuring five-lug patterns: Use a dedicated gauge or online calculator. 3. Uncertainty about tools: Consult online resources or a mechanic. 4. Damaged lugs: Replace before measuring. 5. Inconsistent measurements: Re-measure multiple times.

FAQ: 1. What is PCD? (Pitch Circle Diameter) 2. Why is it important? (Safety and proper fitment) 3. How do I measure it? (See guide above) 4. What tools do I need? (Ruler, caliper, gauge) 5. What if I get it wrong? (Risk of wheel detachment) 6. Can I do it myself? (Yes, with care) 7. Where can I find more information? (Online resources) 8. What if my car has aftermarket wheels? (Measure carefully, previous modifications might affect measurements).

Tips and Tricks: Clean the mounting surface of the wheel hub before measuring. Use a caliper for increased accuracy. Consult online forums for car-specific information.

In conclusion, understanding and accurately determining your car's lug nut pattern is essential for safe and smooth driving. From the historical development of standardized patterns to the practical steps involved in measuring, this seemingly small detail plays a significant role in maintaining the integrity of your vehicle. By taking the time to learn the correct procedures and utilizing the right tools, you can ensure proper wheel fitment, prevent costly mistakes, and most importantly, prioritize your safety on the road. Don't let this crucial measurement be an afterthought. Invest a little time in learning the basics, and your wheels will thank you. Accurate lug nut pattern measurement empowers you to choose the right wheels confidently, avoid potential mechanical issues, and enjoy a safe and enjoyable driving experience. So, grab your tools, get measuring, and take control of your wheel destiny! Remember, a little knowledge goes a long way in ensuring a smooth ride.

Unlocking the power of behr white paint with gray undertones

The hidden language of the laughing crying mask meme

Mastering nfs unbound billboard locations