In the intricate dance of electrical circuits, where currents flow and signals flash, lies a humble yet crucial component: the normally closed (NC) limit switch. Its symbol, a seemingly simple arrangement of lines and curves, embodies a world of control and safety. But what whispers of ingenuity does this symbol hold, and how does it orchestrate the complex interplay of machinery and automation?

Imagine a world without the ability to automatically stop a process, a conveyor belt relentlessly churning, a robotic arm extending beyond its designated reach. The normally closed limit switch acts as a vigilant sentinel, interrupting the flow of electricity when a physical limit is reached. This seemingly small action has profound implications for safety, preventing damage, and ensuring the smooth operation of countless systems.

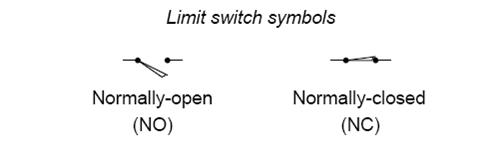

The symbol for a normally closed limit switch, often found nestled within circuit diagrams, tells a story of its inherent function. It depicts a switch contact that is, in its resting state, connected, allowing current to flow. Only when the switch is activated, typically by physical contact with a moving part, does the circuit break, halting the flow. This fundamental principle underlies the switch's role in safeguarding equipment and personnel.

The history of the limit switch is intertwined with the rise of industrial automation. As machines became more complex and operations more automated, the need for reliable safety mechanisms became paramount. The NC limit switch emerged as a simple yet effective solution, providing a tangible link between the physical world and the electrical domain. Its adoption revolutionized safety protocols and paved the way for more sophisticated control systems.

Understanding the function of a normally closed limit switch is crucial for anyone working with electrical circuits. The “normally closed” designation signifies that the switch contacts are closed in their default state. This means that the circuit is complete, and current can flow freely. When the switch actuator is depressed or triggered by a physical object, the contacts open, breaking the circuit and stopping the flow of electricity. This break signals the controlled device to stop, change direction, or perform another predetermined action. For example, on a conveyor belt, an NC limit switch might be positioned at the end. When a box reaches the end and activates the switch, the circuit breaks, stopping the conveyor and preventing the box from falling off.

The normally closed limit switch offers several benefits. First and foremost is its safety function. By halting operations when a limit is reached, it prevents damage to equipment and protects personnel from harm. Secondly, it enhances efficiency by automating processes and eliminating the need for manual intervention. Finally, it offers reliability and simplicity, making it a cost-effective solution for a wide range of applications.

Implementing a normally closed limit switch effectively requires careful planning and consideration. The type of switch, its location, and its wiring must be chosen according to the specific application. Proper installation and testing are crucial for ensuring reliable operation and preventing malfunctions.

Advantages and Disadvantages of Normally Closed Limit Switches

| Advantages | Disadvantages |

|---|---|

| Enhanced Safety | Susceptible to Mechanical Wear |

| Improved Efficiency | Can be Affected by Environmental Factors (Dust, Moisture) |

| Simple and Reliable Operation | Limited Sensing Range Compared to Other Sensor Types |

Frequently Asked Questions:

1. What is the difference between a normally closed and normally open limit switch? A normally closed limit switch completes the circuit when not activated, while a normally open switch completes the circuit when activated.

2. What are common applications for NC limit switches? NC limit switches are used in applications such as conveyor belts, safety interlocks, and robotic arm control.

3. How do you wire a normally closed limit switch? Typically, one wire connects to the common terminal, and the other connects to the normally closed terminal.

4. How do you troubleshoot a faulty NC limit switch? Check the wiring, inspect the actuator for damage, and use a multimeter to test continuity.

5. What safety precautions should be taken when working with limit switches? Always disconnect power before working on circuits involving limit switches.

6. What are the different types of NC limit switches? There are various types based on actuator style, such as lever, roller, and plunger switches.

7. How do you choose the right NC limit switch for an application? Consider factors such as the operating environment, the type of actuator needed, and the electrical rating.

8. How can I test a normally closed limit switch? You can use a multimeter to check for continuity between the terminals.

Tips and Tricks: Ensure proper wiring and regularly inspect for mechanical wear or damage. Consider environmental factors like dust and moisture that might affect performance.

In conclusion, the normally closed limit switch symbol, though deceptively simple, represents a powerful concept in electrical control and automation. From preventing industrial accidents to ensuring the smooth operation of complex machinery, its role is indispensable. By understanding its function, appreciating its benefits, and adhering to best practices for implementation, we can harness the power of this unassuming component to enhance safety, efficiency, and control in a multitude of applications. As technology continues to evolve, the fundamental principles embodied by the NC limit switch will continue to be an integral part of our automated world, silently safeguarding and enabling progress in countless ways. Embrace the power of the small things; they often hold the key to great achievements.

Remembering bob penny forrest gump actor and beyond

Exploring the landscape of adult genshin impact content

Sherwin williams pewter green cabinets a deep dive